Corrosion Laboratory

In our corrosion laboratory, we investigate the behaviour of metallic materials under defined and reproducible conditions. The focus lies on standardized testing and application-oriented interpretation of results.

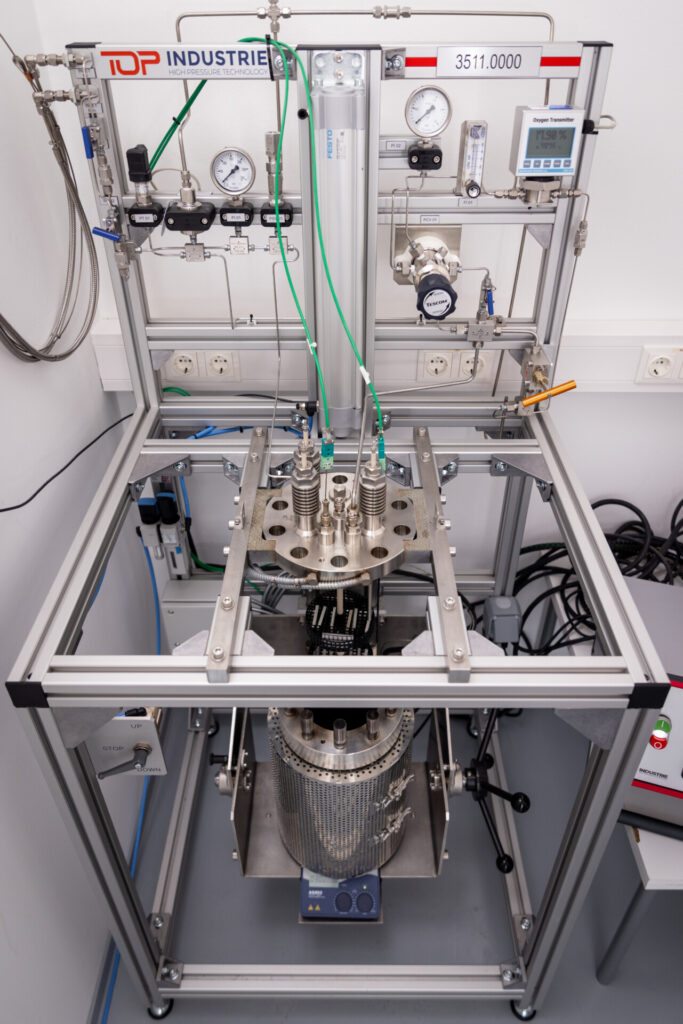

High-pressure / high-temperature autoclave test rig

Our high-pressure, high-temperature autoclave test rig enables corrosion and electrochemical investigations under realistic process conditions. It combines high pressure, high temperature and controlled process chemistry in a stable long-term testing environment.

Detailed description

The autoclave test rig is designed for the realistic simulation of industrial process conditions. It enables long-term exposure testing as well as electrochemical corrosion measurements under controlled thermal, pressure and chemical environments.

A key distinguishing feature is the capability to test not only material specimens but also active sensor systems and electrically powered components directly inside the autoclave. The system provides up to six electrical feedthroughs in the autoclave lid, allowing sensors, probes and other electrical assemblies to be operated and monitored under high-pressure and high-temperature conditions. This makes the test rig particularly suitable for validating sensor concepts and predictive maintenance solutions under realistic process conditions.

Technical details

- Internal volume: approx. 5.15 liters

- Maximum design pressure: 350 bar

- Maximum design temperature: 250 °C

- Typical operating temperature: up to approx. 210 – 230 °C

- Stirring speed: up to 1,000 rpm

- Test duration: from several hours up to >15 days

- Sample arrangement: multiple sample baskets

Materials of construction:

- Pressure-bearing components: superduplex stainless steel 1.4477

- Wetted internal liner: Wetted internal liner: tantalum–tungsten alloy (Ta-2.5W)

Electrochemical capabilities:

- OCP / ECP

- LPR

- EIS

- Long-term electrochemical monitoring

Feel free to contact us if you require corrosion testing or sensor validation under realistic process conditions – we will work with you to develop a suitable test concept for your application.

Additional Testing Equipment

The EmStat4X HR by PalmSens is a high-resolution, modular potentiostat/galvanostat designed for advanced electrochemical measurements. It covers a wide current range up to 200 mA with high resolution and supports measurement techniques such as OCP, LPR, EIS, potentiodynamic polarization (PDP), chronoamperometry and chronopotentiometry.

EC-Pen – Handheld Electrochemical Sensor

The EC-Pen is a mobile corrosion measurement system for fast and non-destructive determination of electrochemical properties directly on metallic surfaces. It is ideally suited for weld inspection, process optimization and quality control.

The EmStat4X HR by PalmSens is a high-resolution, modular potentiostat/galvanostat designed for advanced electrochemical measurements. It covers a wide current range up to 200 mA with high resolution and supports measurement techniques such as OCP, LPR, EIS, potentiodynamic polarization (PDP), chronoamperometry and chronopotentiometry.

Fume Hoods

MPC² operates two Köttermann fume hoods for safe chemical and electrochemical corrosion testing.

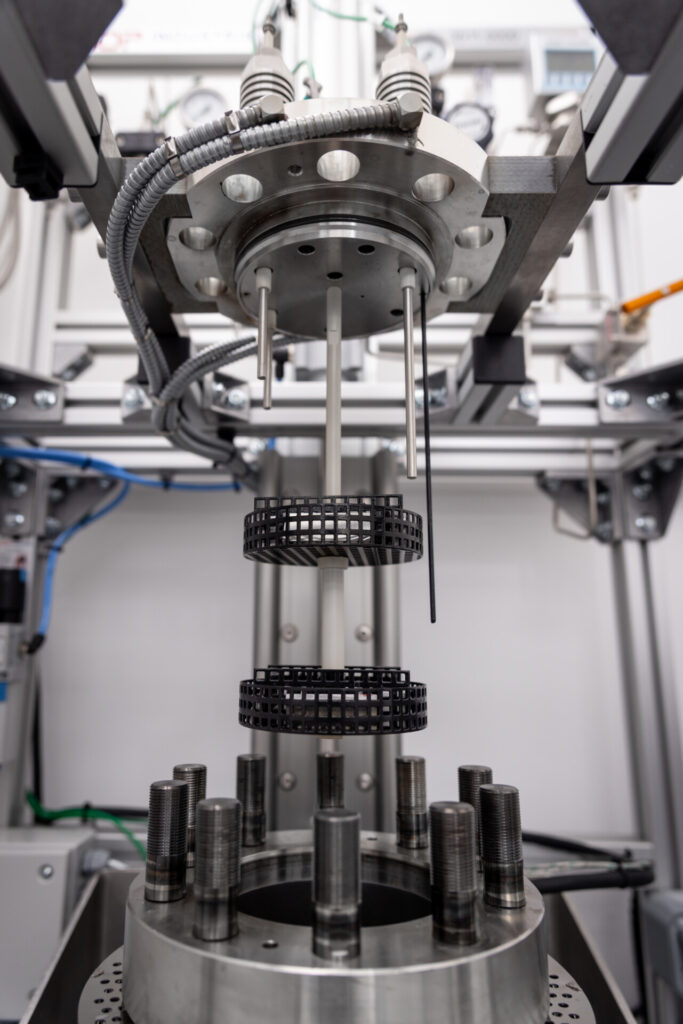

Corrosion Test Rig – ASTM A262 B & C / ISO 3651-1 & -2

The test rig enables standardized intergranular corrosion testing with parallel specimen evaluation.

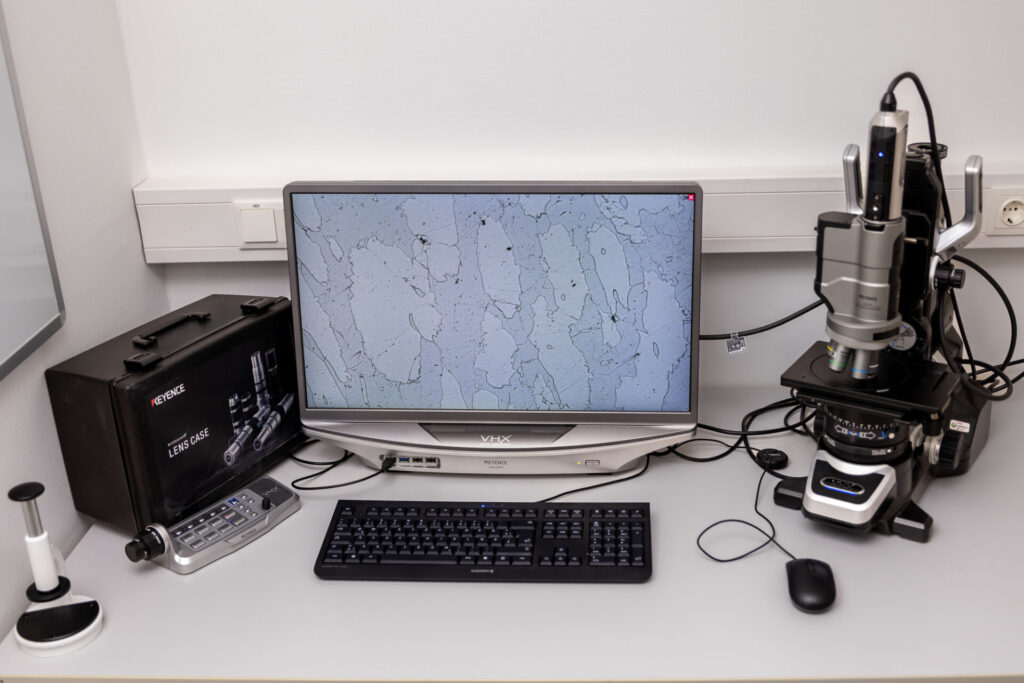

Keyence VHX-970 FN – Digital Microscope (20x – 2000x)

High-resolution 3D digital microscope for detailed surface, microstructural and corrosion analysis.